Titanium Sintered Porous Sheet Filter Titanium Porous disc filter elements

Description

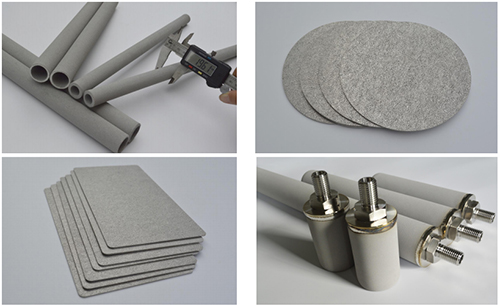

Product Name: Sintered Porous titanium plate titanium sheet titanium disc

Titanium Grade:Gr1/Gr2 Titanium

Titanium Density: 4.51g/cm3

Other materials: Stainless steel, Copper, Plastic, Nickel, Duplex, Super alloy

Shape: round discs, sheet, tube, cartridge, rods, square, ring or according to client's drawings

Sizes:10mm-1200mm 0.4”-47” thickness: 0.5mm-30mm 0.02”-1.2”

Filter Rating: 50-99.9% Pore Size:5-100um

Porosity:20-50% Filtration precision:0.5-70um

Technique: powder sintering technique

Filter media: porous metal

Working temperature: max.:300 ℃ (wet)

Allowable working environment:

Nitric acid, phosphoric acid, 5% hydrochloric acid, molten sodium, nitrogen, hydrogen sulfide, acetylene, water vapor, carbon dioxide gas, acetic acid, sulfuric acid, oxalic acid, liquid hydrogen, hydrogen gas, ect.

What is sintered porous titanium sheet?

Titanium sintered porous sheet is industrial high purity titanium powder as raw material. Sintered porous titanium is sintered by high temperature after titanium powder treatment and a special molding process. Sintered porous titanium filters consisted of high uniform, interconnected networks of pores with tortuous paths that trap solid particles of the gas or liquid flow streams. It has high porosity and environmental carrying capacity.

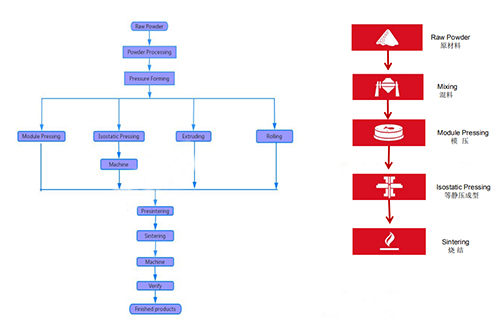

The Manufacturing process of titanium sintered porous sheet

• Titanium Powder Washing and Drying

• Module Pressing

• Cold Isostatic Pressing

• Vacuum Sintering

Titanium material chemical composition

|

Grade

|

CHEMICAL COMPOSITION (weight %, max or range)

|

MECHANICAL PROPERTIES (min)

|

|

ASTM

|

UNS

|

N

|

C

|

H

|

Fe

|

O

|

Ti

|

Other element (each)

|

Other element (total)

|

Tensile

|

Yield

|

El.

|

Red.

|

|

Mpa

|

Mpa

|

%

|

%

|

|

GR 1

|

R50250

|

0.03

|

0.08

|

0.015

|

0.2

|

0.18

|

Bal.

|

<0.1

|

<0.4

|

240

|

138

|

24

|

30

|

|

GR 2

|

R50400

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

Bal.

|

<0.1

|

<0.4

|

345

|

275

|

20

|

30

|

Titanium sintered porous sheet Application

• Food and beverage

• Water treatment

• Chemical

• Biological engineering

• Metallurgy

• Sewage treatment

• Electrolytic water

• Metallurgy

• Energy Storage Battery

• Pharmaceutical industry

• Environmental detection

• Natural gas,

• impurity filter

The advantages and features of Titanium sintered porous sheet

• Uniform distribution of particles

• No slag beautiful appearance

• Good chemical stability, acid ,and alkali corrosion, excellent oxidation resistance

• Good mechanical performance, low pressure and high flow

• Regenerated online, easy to clean, long service life

• Strong resistance to the microbe, no action with microorganisms

• High porosity, small filtration resistance and high permeability

• High-temperature resistance, usually it could work normally in less than hygrometric state 250℃

Hot Tags: Sintered porous titanium disc, Titanium Porous Filter Metal Sheet, Powder sintered titanium alloy filter element, titanium sintered powder porous filter disc rods, Porous Titanium Sintered Filter, Sintered porous metal filter,

The titanium porous metal filter element produced is completely passed through with titanium powder or titanium metal fiber; It is made by high-temperature sintering. The combination of this special process and titanium metal materials enables the majority of users to obtain technical advantages and economic benefits.

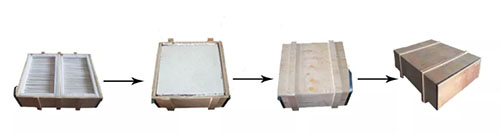

Package Terms:

Moisture-proof cloth, foam cotton inside, Plywood case or Carton case outside.

Shipping Terms:

1. For the sample order: By international express such as: DHL, TNT, EMS, UPS and so on.

2. For large quantity: By air or sea transport.

Attn: Jason

Email: jasontitanium@163.com

Whatsapp/Skype/Wechat/Line: +86-15829508781