Ruthenium Iridium Ru-Ir Titanium Anode Mesh and Plate for electrolysis

Description

Mixed Ru-Ir Oxide Coating MMO Titanium Anode Mesh and Plate

Material Grade:Gr1/Gr2 Titanium as substrate, mixed Ruthenium Iridium (Ru-Ir) , Iridium Tantalum (Ir-Ta), PbO2 , Platinum(Pt), and Titanium oxide as coating

Material Density: 4.51g/cm3

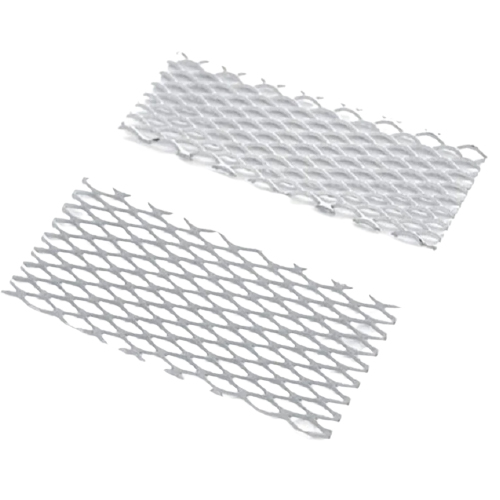

Shape: mesh, rod, wire, plate, tubular, box, ring, ribbon, basket, or according to client's drawings

Regular sizes: 50mm-300mm 2”-12” thickness:0.8mm-3mm 0.03”-0.12”

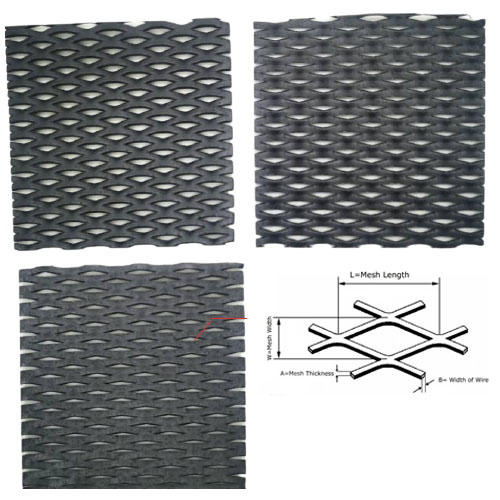

Mesh size: 0.3×0.5mm, 0.6×1.2mm, 1×2mm, 1.5×3mm, 1.5×2.5mm, 2×3mm, 2×4mm, 3×4mm, 3×6mm, 4×8mm, 5×10mm, 4.5×12.5mm, 14×40mm:

Technique: Brush Coating, Sand blasting, Acid washing

Coating: Ruthenium Iridium (Ru-Ir) , Iridium Tantalum (Ir-Ta), PbO2 , Platinum(Pt) etc

Coating Thickness: 0.5~5 um micron

What is MMO Titanium anode?

MMO Titanium anode is called Mixed Metal Oxide titanium anode or Dimensionally Stable Anode (DSA), Dimensionally Stable Electrode (DSE). The coating of precious metal oxide with titanium metal as the substrate such as Ru-Ir, Ir-Ta, PbO2, Platinum, etc. The heat-treating precious coating produces changes in chemical composition and morphology that improve its electric catalytic activity and electrical conductivity. Titanium anodes are used in corrosion resistance and high electrical conductivity environments.

How to process the titanium anode mesh and plate?

• Start with substrate treatment: Clean the titanium substrate and remove surface oil. This is treated by a chemical etching and rough. It can increase the compactness of catalytic.

• Brush coated and dry anode: Once the substrate surface is complete. it will start to brush coated. The main coated are a solution containing soluble compounds of the precious mixed metal oxide.

• Heat Treatment: Heat treatment will be going on after drying. The coated is thermally treated with temperatures ranging from 400-600°C. This forms an adherent layer of mixed metal oxides. The whole process needs to be repeated many times.

Titanium material chemical composition and mechanical properties

|

Grade

|

CHEMICAL COMPOSITION (weight %, max or range)

|

MECHANICAL PROPERTIES (min)

|

|

ASTM

|

UNS

|

N

|

C

|

H

|

Fe

|

O

|

Ti

|

Other element (each)

|

Other element (total)

|

Tensile

|

Yield

|

El.

|

Red.

|

|

Mpa

|

Mpa

|

%

|

%

|

|

GR 1

|

R50250

|

0.03

|

0.08

|

0.015

|

0.2

|

0.18

|

Bal.

|

<0.1

|

<0.4

|

240

|

138

|

24

|

30

|

|

GR 2

|

R50400

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

Bal.

|

<0.1

|

<0.4

|

345

|

275

|

20

|

30

|

MMO Titanium anode Application

• Cathodic protection

• Waste Water Treatment

• Electroplating

•Chlor-Alkali Industry

• Sewage treatment

• Electrodialysis

• Electrolytic water

• Metallurgy

• Energy Storage Battery

• Cooling Water Treatment in Chemical

• Extract Copper or Nickel by vortex electrolytic

•Alkaline & Acidic water production

•Water ionizer

The advantages and features of MMO Titanium Anode

•Long working life.

•High property of current efficiency & catalysis

•High anti-corrosion property

•The titanium material is recyclable

•No pollution of the cell

•Light weight

•Stable working ability under high current density & Voltage

•Low working voltage, save power/electricity

Hot Tags: Platinized titanium anode, Titanium anode mesh, Titanium anode, MMO titanium anode, Ruthenium Iridium titanium anode, titanium niobium oxide anode, platinum-plated titanium anode,

We can offer titanium anode in the shape of the mesh, plate, rod, tube and customize the shape anode. The mesh and plate are normally in plating, electroanalysis and water treatment. The rod and tube normally use in cathodic protection.

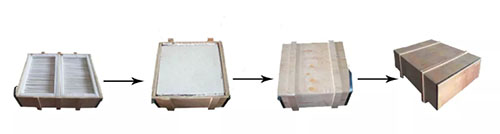

Package Terms:

Moisture-proof cloth, foam cotton inside, Plywood case or Carton case outside.

Shipping Terms:

1. For the sample order: By international express such as: DHL, TNT, EMS, UPS and so on.

2. For large quantity: By air or sea transport.

Attn: Jason

Email: jasontitanium@163.com

Whatsapp/Skype/Wechat/Line: +86-15829508781