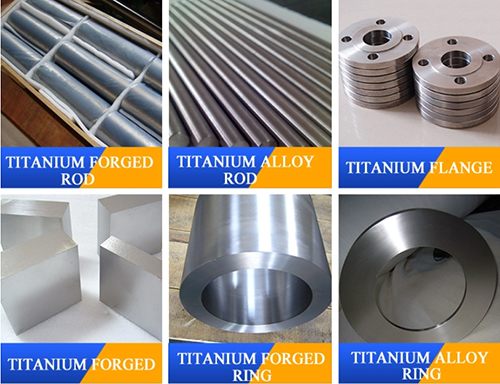

Gr5 ASTM B381 Titanium and Titanium alloy Forged Ring

Product name: ASTM B381 Forged Titanium Rings/Titanium Disc

Density: 4.51g/cm3

Standard: ASME SB381, ASTM B381, AMS 4928, GB/T16598-2013

Size:

OD(60-1300)*ID(50-900)*H(10-600)mm

Grade:

TA1-TA3, TA8-TA10, TA17, GR1,GR2,GR3,GR4,GR5, GR7, GR9, GR11, GR12, Gr23, Ti-6AL-4V

Color.: sliver

Surface: Polished, Machining,

Application:

industry, electronics, medical, chemical, petroleum, pharmaceutical, aerospace, etc.

Feature:

1. Low Density and High Specification Strength

2. Excellent Corrosion Resistance

3. Good Resistance to Effect of Heat

4. Excellent Bearing to Cryogenics Property

5. Nonmagnetic and Non-toxic

6. Good Thermal Properties

7. Low Modulus of Elasticity

Titanium strength/density ratio is better than other metals, components with high strength, less weight can be made out of titanium. Titanium is applied for aircrafts engines, frames, skins, and landing gears.

Titanium alloys still owns its mechanical properties when working in low or super low temperature conditions. Titanium alloys with low-temperature and extra low interstitial still possess good ductility, therefore, titanium alloy is sort of good low temperature structural material.

|

Grade

|

N

|

C

|

H

|

Fe

|

O

|

Al

|

V

|

Pd

|

Mo

|

Ni

|

Ti

|

|

Gr1

|

0.03

|

0.08

|

0.015

|

0.2

|

0.18

|

/

|

/

|

/

|

/

|

/

|

Remain

|

|

Gr2

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

/

|

/

|

Remain

|

|

Gr3

|

0.05

|

0.08

|

0.015

|

0.3

|

0.35

|

/

|

/

|

/

|

/

|

/

|

Remain

|

|

Gr4

|

0.05

|

0.08

|

0.015

|

0.5

|

0.4

|

/

|

/

|

/

|

/

|

/

|

Remain

|

|

Gr5

|

0.05

|

0.08

|

0.015

|

0.4

|

0.2

|

5.5~6.75

|

3.5~4.5

|

/

|

/

|

/

|

Remain

|

|

Gr7

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

0.12~0.25

|

/

|

/

|

Remain

|

|

Gr9

|

0.03

|

0.08

|

0.015

|

0.25

|

0.15

|

2.5~3.5

|

2.0~3.0

|

/

|

/

|

/

|

Remain

|

|

Gr12

|

0.03

|

0.08

|

0.015

|

0.3

|

0.25

|

/

|

/

|

/

|

0.2~0.4

|

0.6~0.9

|

Remain

|

Packing

Plywood case or According to customer requirements

Email: jasontitanium@163.com

Whatsapp/Skype/Wechat/Line: +86-15829508781