Nitinol Rods Shape memory alloy bars Superelastic Niti Rods Niti Wire

Name: Nitinol Superelatic SMA alloy Niti Rods&Bars for experimental materials

Niti Density: 6.45g/cm3 or 0.234 lb/in3

Standard: ASTM F2063-12,ASTM F2633

Nitinol Grade: Ni-Ti-01, Ni-Ti-02, Ni-Ti-SS, TN3, TNC, Ni-Ti-Cu, Ni-Ti-Fe, Ni-Ti-YY

Af Temperature range: -20°C to 120°C

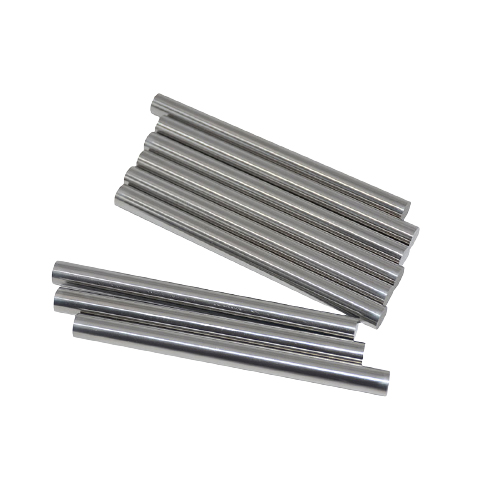

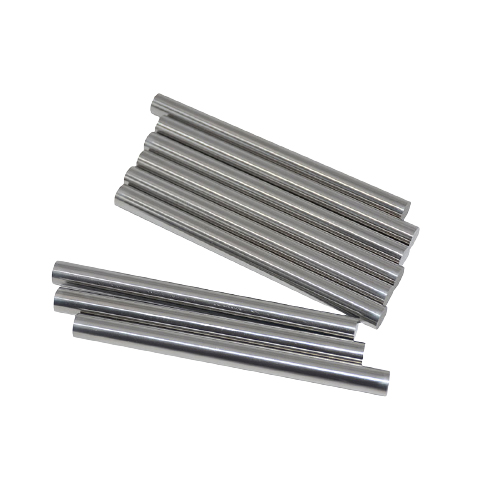

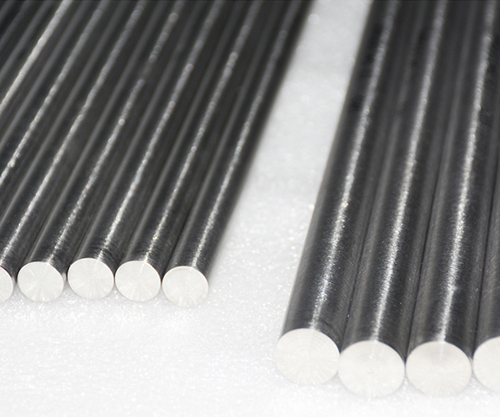

Size: Dia0.1mm to Dia100mm Length:100-2000mm

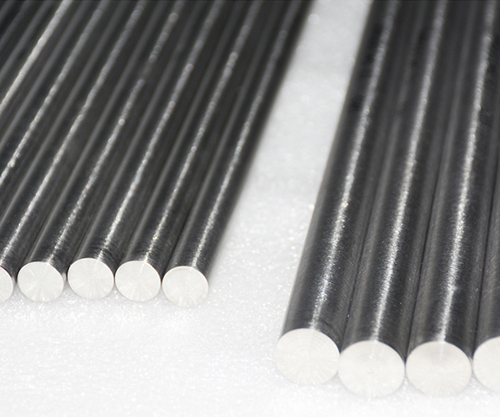

Surface:Polished, Black, Machining, Pickling ,Bright

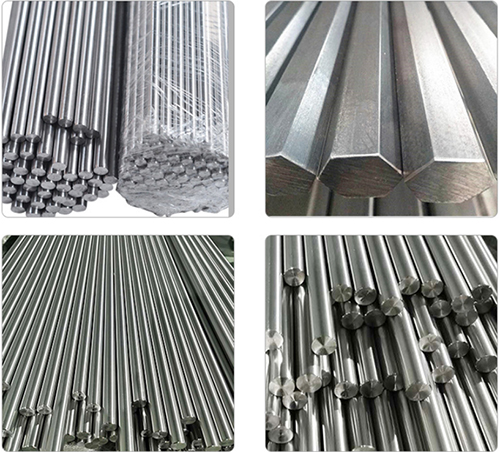

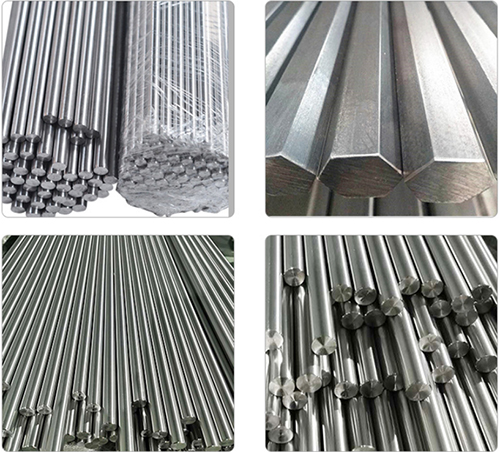

Type:Round Rods ,Flat Rods, Wires, Square bars, Hexagonal bars

Conditions: Cold-Worked, Straight Strain Annealed, Shape Set Annealed

Color: Silver, Black

What are nitinol and SMA?

Shape memory alloys (SMA) are alloys with "Memory": They can return to their original shape after being deformed via a change in pressure or temperature. SMA are used in a wide variety of applications - including metallurgy, manufacturing, biomedicine, and children's arts and crafts. The shape memory alloy is a material that goes through a stage change when it encounters a mechanical pressure or temperature change. At the point when the conditions recover to business as usual, the SMA "remembers" its original shape and reverts to it. Nitinol Shape Memory Alloys undergo a phase transformation in their crystal structure when cooled from the stronger, high temperature from (Austenite) to the weaker, low temperature from (Martensite). This inherent phase transformation is the basis for the unique properties of these alloys in particular, Shape Memory and Superelasticity.

Superelastic Effect

An elastic (reversible) responses to an applied temperature, caused by a phase transformation between the austenitic and martensitic phases of a crystal.

Ms- Initial temperature for austenite to martensite transition

Mf- Final temperature for austenite to martensite transition

As- Initial temperature for martensite to austenite transition

Af- Final temperature for martensite to austenite transition

Shape Memory Effect

"Shape Memory Alloy" SMA describes the restoration of the original shape of a plastically deformed sample upon heating.

Application:

experimental materials, cell phone antennas, eyeglasses components and medical equipment., biomedicine, metallurgy, fishing rod, Nitinol catheter stents, aerospace release mechanisms, hot water scald-prevention valves, arch wires, surgical stitching wire, Super spring,

Nitinol Feature

• Super-elastic and Shape memory alloy(SMA)

• Melting Temperature: 1240-1310° C

• Thermal Conductivity: 0.1 W/cm-° C

• Heat Capacity: 0.077 cal/gm-° C

• Typical Yield Strength (hi-temp): 560 MPa, 80 ksi

• Typical Yield Strength (lo-temp): 100 MPa, 15 ksi

• Tensile strength: ≥890Mpa

• Low Density and High strength

|

Chemical Composition

|

Ti

(%)

|

Fe

(%)

|

C

(%)

|

O

(%)

|

N

(%)

|

H

(%)

|

Co (%)

|

Ni

(%)

|

|

Remainder

|

0.008

|

0.044

|

0.026

|

0.00 2

|

0.001

|

/

|

55.7

|

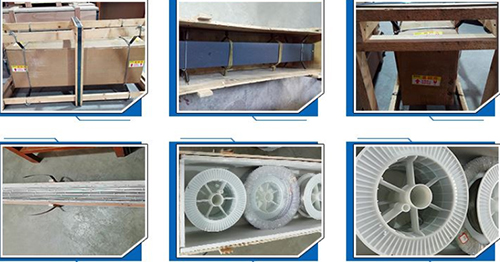

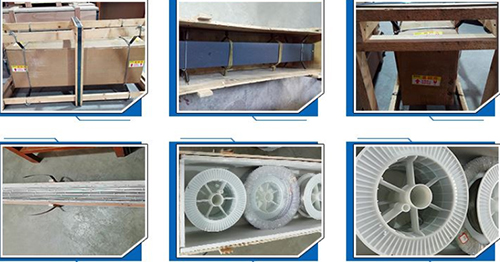

Package Terms:

Moisture-proof cloth, foam cotton inside, Plywood case outside.

Shipping Terms:

1.For the sample order: By international express such as: DHL, TNT, EMS, UPS and so on.

2. For large quantity: By air or sea transport.

Attn: Jason

Email: jasontitanium@163.com

Whatsapp/Skype/Wechat/Line: +86-15829508781

Titanium and Titanium alloy

Titanium and Titanium alloy