Titanium alloy processing technology

Vacuum melting technology

The vacuum smelting furnace for smelting alloy steel is used to heat and melt the titanium alloy into a liquid through the eddy current generated in the furnace. The advantage is that the whole process is carried out in a vacuum, thereby preventing impurities in the air from entering the metal and smelting a high quality alloy. .

Isothermal forging technology

Die forging by heating the mold to the deformation temperature of the blank and deforming at a low strain rate is called isothermal forging.

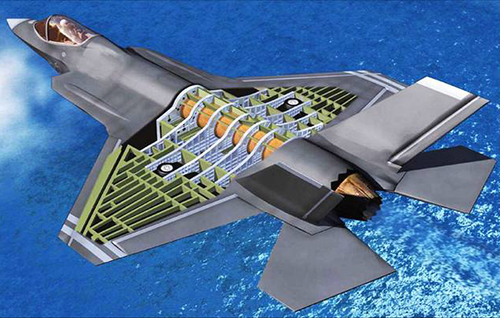

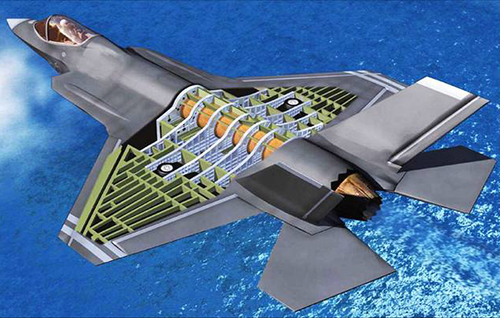

Titanium alloy isothermal forging technology is a new process. Combined with thermomechanical treatment, it can obtain titanium alloy isothermal forgings with optimized mechanical properties. However, the cost investment in mold materials, mold manufacturing and mold heating devices is higher than conventional forging methods. Mostly used to make parts for aircraft.

Cold forming

In the case where heating is not performed, a processing method of punching, bending, stretching, or the like of the titanium alloy is referred to as cold forming.

Special processing technologies for titanium alloys include laser processing technology, electron beam processing technology, ion beam and plasma processing technology, and electrical processing technology. Titanium alloys are processed using these techniques depending on cost options.

Surface treatment

A process for artificially forming a surface layer different from the mechanical, physical and chemical properties of the substrate on the surface of the base titanium alloy material.

According to the characteristics of titanium alloy, the current surface treatment technology of plasma infiltration, ion beam, electron beam, laser beam, etc. is mainly to improve the wear resistance, corrosion resistance, fretting wear resistance and high temperature of titanium alloy. Oxidation resistance, etc.

Email: jasontitanium@163.com

Whatsapp/Skype/Wechat/Line: +86-15829508781

Titanium and Titanium alloy

Titanium and Titanium alloy