Surface modification of biomedical titanium alloy to improve wear resistance

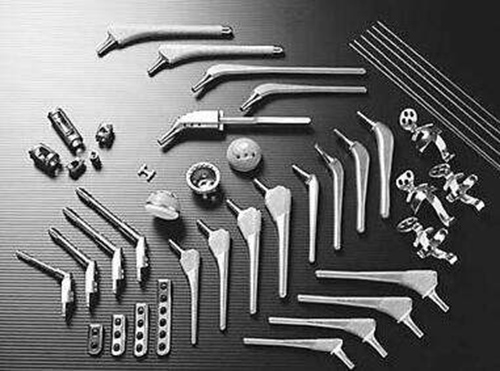

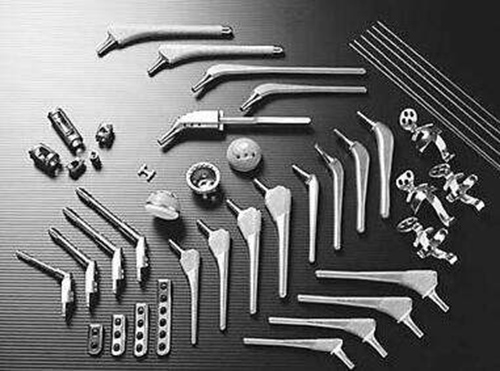

Titanium and its alloys have the advantages of low density, high strength, non-toxicity, and corrosion resistance. They are the most commonly used medical implant metal materials in orthopedics and dental applications. The elastic modulus of titanium alloy is lower than that of traditional stainless steel and cobalt-based alloys. The low elastic modulus can reduce the stress shielding effect, thereby better inducing and promoting bone healing, and is more suitable for clinical applications.

However, titanium and its alloys cannot meet the clinical needs of biomedical implants. Long-term clinical studies have found that the wear resistance of titanium implants is poor, and the wear debris generated by the friction of titanium implants may cause inflammatory reactions and toxic effects on the human body.

In order to improve the biological properties of titanium alloys, the use of surface modification technology to improve the biological activity, wear resistance and antibacterial properties of titanium and titanium alloys is a more economical and effective way to improve the existing conventional biological materials to meet their performance. The current and evolving clinical needs of the method.

At present, in order to improve the wear performance of the titanium alloy surface, a variety of physical and chemical methods are used, and a ceramic coating with excellent wear resistance is deposited on the surface of the titanium alloy to improve the wear and corrosion performance of the titanium alloy. Commonly used wear-resistant coatings include diamond-like carbon (DLC) and titanium nitride (TiN) coatings.

Diamond-like carbon film (DLC)

Diamond-like carbon film has the advantages of high hardness, good wear resistance, low friction coefficient, and good biocompatibility. It is often used as a wear-resistant coating for medical metal implants. Some implant devices with surface modification of diamond-like carbon film have been used in clinics, and have broad application prospects in improving the wear resistance and corrosion resistance of artificial joint metal components.

Titanium Nitride (TiN)

Titanium nitride has good wear resistance and corrosion resistance, and was first used for cutting tools to extend their service life. It was later discovered to be biocompatible and has been used in medical implants such as plastic surgery and dentures. The current methods for preparing titanium nitride mainly include physical vapor deposition (PVD), chemical vapor deposition (CVD) and thermal spraying.

Email: jasontitanium@163.com

Whatsapp/Skype/Wechat/Line: +86-15829508781

Titanium and Titanium alloy

Titanium and Titanium alloy